Prodotti

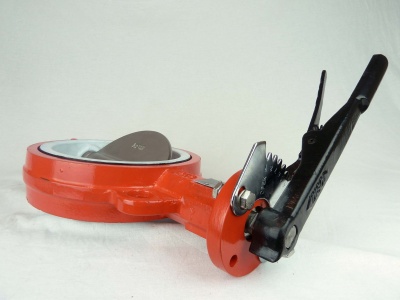

Control valves

The control or modulating valves are devices that are used to control the flow rate of the fluid during the industrial process. All this takes place by adjusting the shutter position between the valve's opening and closing position.

The valves' control can be linear or of equal percentage. There is an increase in the flow rate following the steady increase of the valve opening in the linear control for the entire stroke of the valve itself. Whereas with the equal percentage, the flow increases as a result of the increase of the valve opening and in proportion to the flow itself, thus obtaining the possibility of adjusting the minimum flow in the first part of the valve stroke and modulating those higher in the final part of the stroke.

The opening, closing, and modulating action of the valve are produced by the variation in the pneumatic signal which reaches the servomotor (valve pneumatic cylinder head). The diaphragm/spring combinations provided within the valve's pneumatic cylinder head cover different input signal ranges on the diaphragm.

Italvalvole® control valves are supplied normally closed NC (open air), or normally open NO (closed air). In any event, as the servomotor is reversible, it is possible to transform an NC valve into a NO valve and vice versa, thanks to the simple replacement of a few details.

Control valves can be two-port or three-port and the latter are divided into mixing valves (blend two input fluids) and diverter valves (divert the fluid into two outputs). The most commonly used materials for the valve bodies are grey iron and ductile iron (GJL 250 and GJS 500), carbon steel (WCB) and stainless steel (CF8M).

All the valves have been devised and designed so as to optimise the maximum flow rate and the Kv, and reduce the load losses as much as possible. They are installed in standard process industries, for example in the dyeing industry, the textile industry, in the chemical industry, in thermoregulation processes and in food and pharmaceutical applications.

In case of special applications such as those with steam and when high temperatures up to 300°C are reached, it is possible to equip the valve with bellows and/or a noise-proof cage. In order to obtain control with greater performance, such valves can be equipped with accessories such as inductive, magnetic sensors, microswitches for opening and/or closing and pneumatic or electropneumatic positioning devices.

The commonly intercepted fluids are dyeing baths, glycol, steam, diathermic oil, superheated water, chemical solutions and fluids in general. The valves are designed and manufactured according to 2014/68/EU Directive with connections in accordance with EN 1092 (PN 16 and PN 40 flanged) with threaded attachments, butt welding or socket welding.

Furthermore, Italvalvole® is continuously expanding its range of products and also offers the possibility of producing valves from the technical specifications given by the customer.